A DC planetary gear motor includes a planetary gearbox and a DC motor. It is a kind of driving instrument used to minimize speed and maximize torque. It is a kind of gear arrangement that increases efficiency and power transmission capacities. The most important parameters related to dc planetary gear motors are speed, torque and efficiency.

DC Planetary Gear Motor

Construction of DC Planetary Gear Motor

- DC planetary gear motors are usually cylindrical and are made of steel or brass. Those can also be made of plastic to satisfy different power and size requirements.

- DC planetary gear system includes a central gear, known as a sun gear that makes a network with other tiny gears, known as planet gears. These planet gears are mounted on a carrier that moves around the sun gear.

- Carrier is coupled to the output shaft, and the rotation of the carrier makes the planet gears to move around the sun gear, generating a high-torque output.

Working Principle of a DC Planetary Gear Motor

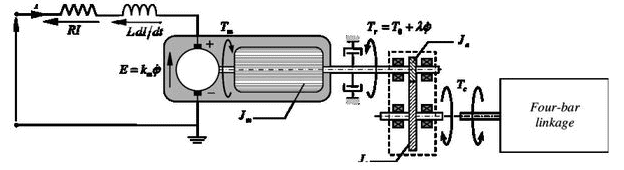

The principle of gear motor working is the same as the operation of a classic electric gear motor.

- The principle of a DC gear motor is that the first portion of it transforms some energy into mechanical energy, and the second portion is made to transmit the remaining mechanical energy to the output shaft to modify its speed.

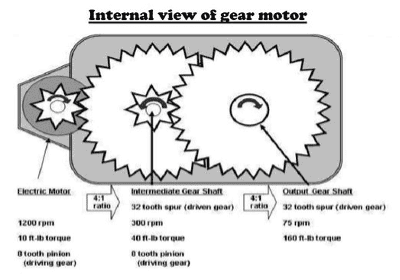

- The torque of the motor is transmitted to the drive pinion that is mounted on the motor shaft. The gear motor drive pinion has cylindrical holes for mounting the drive motor shaft. The gear motor is designed as a mechanical gear combined with an electric motor.

- Output rotation speed relies on the parameters of a motor and the gear ratio. Multistage models are applied to attain a greater conversion ratio. If corrections of speed are needed, geared motors can be incorporated into speed-controlled systems easily through controlled converters.

Performance Curve of a DC Planetary Gear Motor

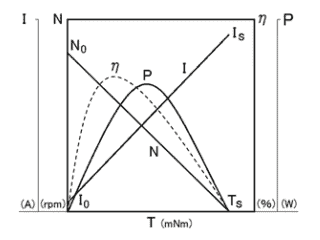

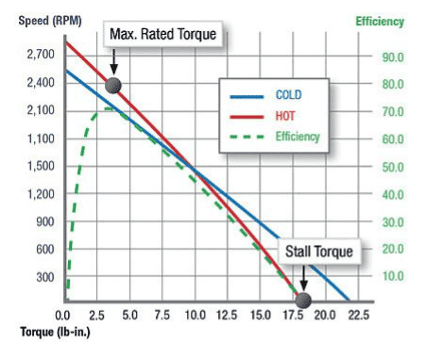

The performance of a motor and the performance of a gearbox are combined into one graph by displaying three specific parameters, such as speed, torque and efficiency. These performance curves are important when selecting a gear motor for application.

- Speed (N): This straight line in the performance curve provides the relationship between torque and speed of a DC planetary gear motor. This line is shifted based on the increment or decrement of voltage.

- Current (I): This straight line displays the relationship between current and torque from no-load to full motor stall.

- Torque (T): This line on the X-axis is the load represented by the motor shaft.

- Efficiency (η): Efficiency is measured using the input and output values shown by the dashed line. It should be used close to its peak efficiency to increase the potential of the DC planetary gear motor.

- Output (P): The quantity of mechanical energy output by the gear motor.

The following power curve for a DC gear motor is an example. The highest operating efficiency (70%) of this DC motor is 2,100 rpm (3.75 lb-in). When torque is increased, speed and efficiency are decreased. Output power is low for the increased torque, and the unit may not operate if the motor reaches its stall torque (18 lb-in).

Advantages of DC Planetary Gear Motor

- High Efficiency: The multiple-gear contacts allow load and minimize wear, creating high efficiency even at high gear ratios.

- Compact Size: The compact design of a planetary gear motor is ideal for miniature applications.

- Accurate Placing: Low backlash inherent to the design of a gear motor allows precise positioning, which is important in robotics and automation applications.

- Torque Density: It gives high torque output compared to its size, providing an excellent power-to-weight ratio.

- Simple Operation: Planetary gear motors are able to show smooth and quiet operation because of the distributed load and meshing action.

- Multipurpose: They have huge applications in various types of industries from automotive systems to medical.

Applications

- Robotics: DC planetary gear motors are very useful for robotics applications because of its precision and compactness

- Industrial Mechanization: They play a vital role in conveyor systems, material handling, and automated machinery through its effective torque delivery.

- Aerospace: They have huge applications for surface adjustments in aircraft

- Automotive: They are widely used in many vehicle systems, such as power windows, seat adjustments, and sunroofs.

- Medical Instruments: They are very useful for medical equipment, such as blood analyzer and surgical instrument, for its precision.

Conclusion

DC planetary gear motors are efficient for providing a high torque-to-size ratio, preciseness, and motion control in compressed space that make them perfect for industrial applications. These motors are available in a wide range of sizes, torque ratings, and configurations. Their complicated design coupled with high efficiency and versatility make them as the ideal driving force for large scale of applications.

Assunmotor’s Certification

Assun Motor has been manufacturing brushed, brushless, servo DC motors, planetary gearboxes, encoders, and bakes since 2003. Our motors are coreless types and they are great for precision engineering tools or equipment, and they last longer than regular DC motors.

We have two certifications, one is a Certificate of Compliance and the other Certificate of Registration.

Find out more about Assunmotor’s Planetary Gear Motors

Due to the many different specifications for our coreless (brushless, brushed, servo) DC motors and planetary gearbox range, we understand that it’s hard to find the right inline DC planetary gear motor for you.

Please contact our friendly sales personnel and they will be able to guide you, simply click the contact us below and fill in your contact details and what you are looking for on the web form.

Latest Posts

Servo Motor Controller: How It Works, Applications & Benefits

In the realm of industrial automation and precision engineering, the ability to control motor movements with high accuracy is crucial. A servo motor...

What is a DC Motor and Its Working Principle?

A Direct Current motor, a DC motor, is an electrical instrument that is operated by direct current and transforms electrical energy into mechanical energy....

What is a DC Motor and Its Working Principle?

Understanding DC Brushless Motor Efficiency & How to Test For It

Brushless DC motors are some of the most efficient and long-lasting motors available on the market today. But what exactly makes them so efficient compared...