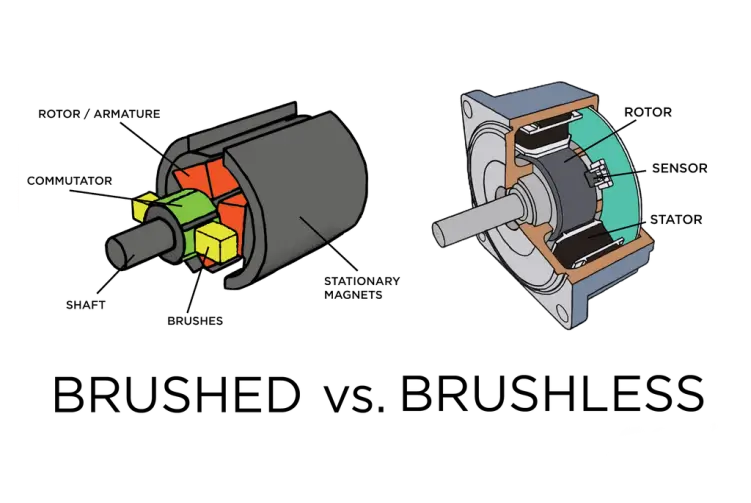

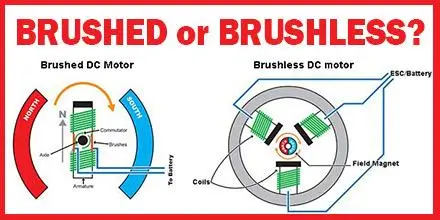

Power instruments, including brushless and brushed DC motors, are very important devices in our daily lives for making difficult tasks into simple and easy ones with higher productivity. It is very necessary to know the difference between brushless and brushed DC motors to have a better understanding of their performances. When comparing brushless and brushed motors is important, the selection and choice between those two DC motors rely on criteria such as efficiency, life span, cost, etc.

Brushless and brushed DC motors are perfect for each specific and different type of application. To have a better understanding of their uses, it is always important to have ideas regarding the differences between them. There are some important factors of differences between brushed and brushless motors that help users select the right one for better applications. Those factors have been discussed in detail below.